Press Drive Systems

Special machines, components and technologies developed in Germany

TOX Core Competencies

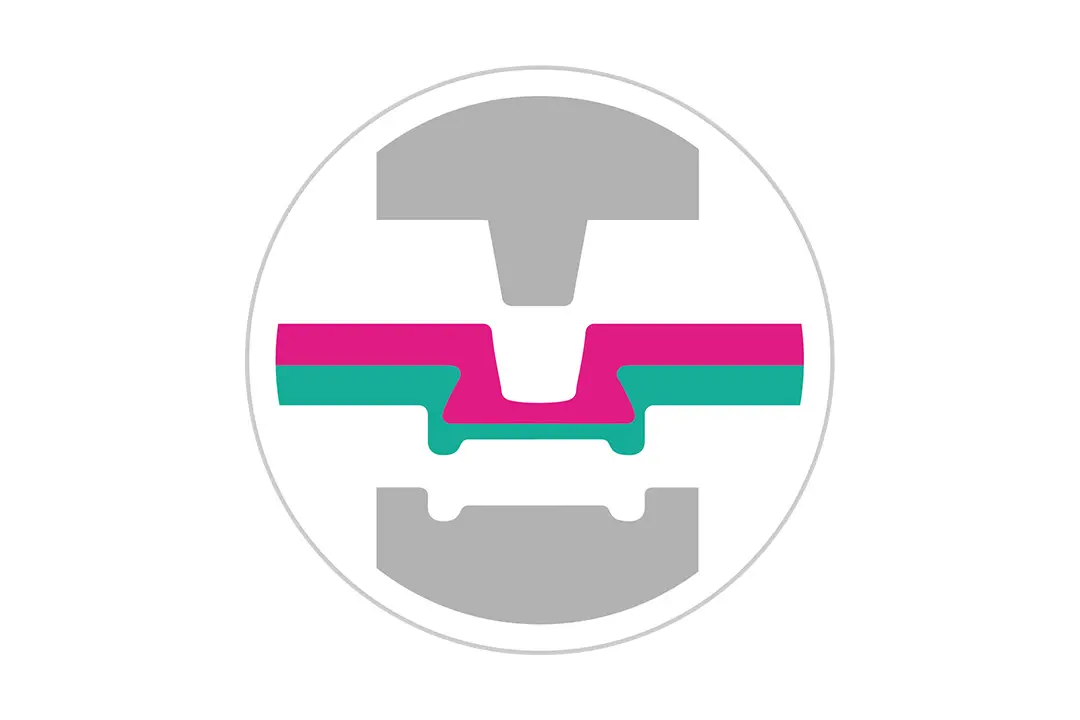

Clinching & E-Clinching

Clinching, clinch joining or “toxing” is an excellent method for permanently joining sheet metal. It is based on efficient cold forming and requires no additional joining elements such as screws or rivets.

Riveting Technologies

Securely join sheet metals, plastic plates or other flat materials with each other. The TOX solution: Semi-hollow punch riveting, solid punch riveting.

Functional Element Insertion

Securely press small joining elements such as nuts, bolts or screws into material? TOX press-in machines and tools process all kinds of functional elements.

Seamstaking

SeamStake technology reliably secures sheet metal components, effectively prevents displacement in the plane direction and is typically used in folded component areas.

Pressing & Crimping

TOX Gaurantees you pressing in and out with absolute precision – from the smallest force ranges all the way up to 2000 kN.

Punching

Whether sheet metal, plastic, cardboard, textiles, or foils – TOX has the know-how ranging from simple punch presses to highly engineered punching systems.

Theta Clinching

The targeted heating of the material combination using a laser before the actual clinching process significantly increases the formability of materials. This allows a reliable mechanical connection even with materials that are difficult or impossible to clinch under normal conditions.

A Trusted Source for press drive systems, sheet metal joining and assembly equipment

18

worldwide locations and numerous branches for support wherever you are

+1500

Employees working at TOX ensuring familiar & personal service

+40

Years of innovation, success, and reliablility

Product Highlights from TOX

Questions about your next automation project?

We’re here to help!